Join us and unlock access to personalized features, exclusive content, and more. Fill in the details below to get started.

Episode 6. A journey to PIV flow measurements at ship scale.

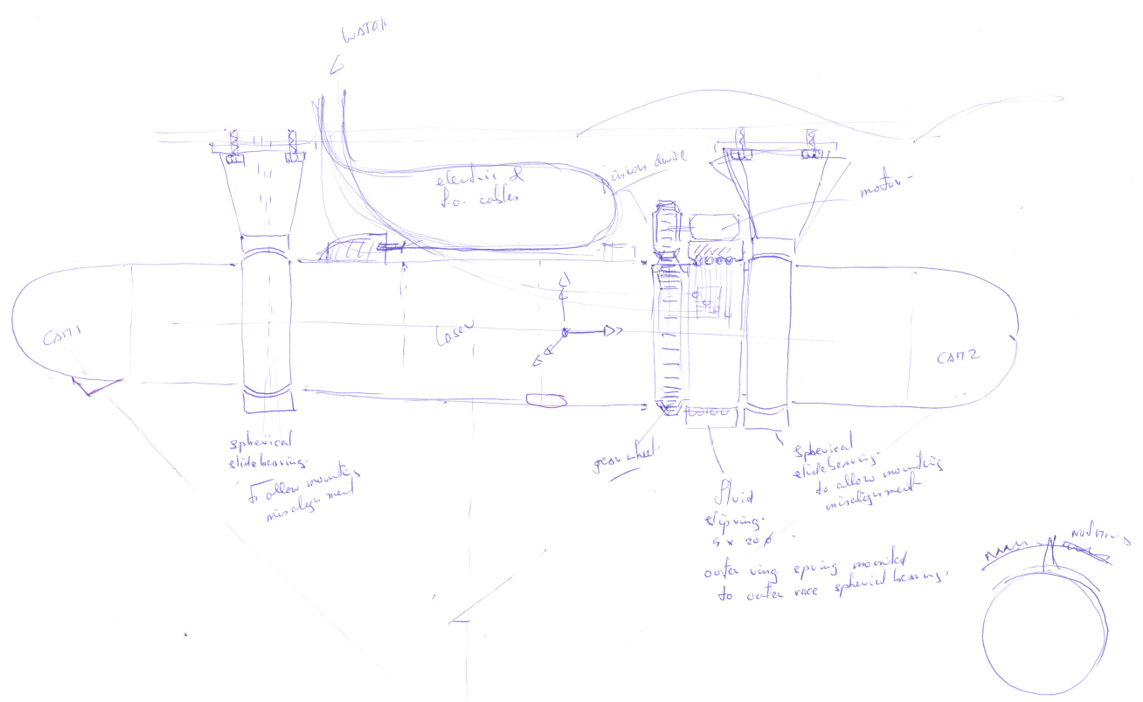

After establishing the viability of the PIV measurement principle at full scale, the design and development of the PIV unit started. Based on previous experience measuring with complex optical devices, it was decided to make the unit:

1) As robust and as sturdy as possible, since it needs to withstand harsh conditions (vibrations, flow forces, salty water) when installed, as well as during transport and handling. The device should be water-tight and include various levels of protection against leakage both into the device, as well as into the vessel.

2) As universally applicable as possible, meaning not dependent on the specific position of portholes or internal structures of the ship. This means mounting the unit outside on the shell plate, thereby also having an unobstructed view of the flow.

3) Able to measure in a large field of view, such that a sufficiently large part of the flow coming into the propeller is measured. This requires the laser energy and the camera resolution to be high. Further, the frequency of the system needs to be as high as possible in order to gather large amounts of data in the limited time available in a run.

4) Free from the requirement to calibrate the device after installing it on the ship. In other words, the device should be as simple as possible to operate. The alignment, calibration and other sensitive activities can be performed in the laboratory, after which the device should be able to work without further intervention in the difficult environment of a sea trial.

With these requirements outlined, it was also decided to divide the work between MARIN and LaVision GmbH (Gottingen, Germany) in the following way: MARIN will lead the overall development and perform the design and engineering of all the mechanical parts of the system whilst LaVision will perform optical design and deliver the necessary optical and electrical components of the system. After this, MARIN will perform the final system assembly, testing and commissioning.

To be continued…

A sketch of the PIV unit for ship scale measurements

A sketch of the PIV unit for ship scale measurements