Join us and unlock access to personalized features, exclusive content, and more. Fill in the details below to get started.

Latest News

How do you know that your Energy Savin

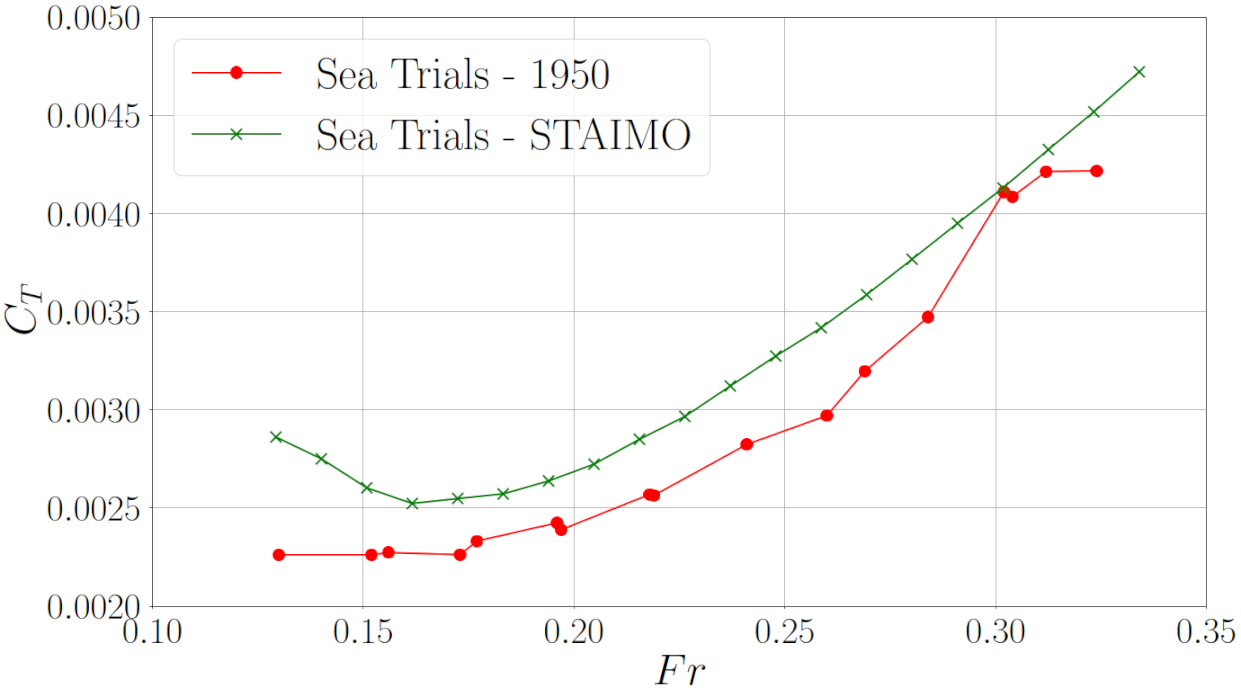

If you perform sea trials on a vessel and, after that, you put her in a dry dock to install an Energ...

See moreWhat did we learn about sea trials pro

We all know that a vessels actual sea trials measurements are affected by many external factors, suc...

See moreNew CFD Workshop on the JoRes2 twin sc

All the previous ship scale validation cases considered under the JoRes project were either single s...

See moreMission

The Joint Research Project mission is to collect and develop, through collaboration, a full set of ship performance data, to better understand the potential for ship energy efficiency.

Collect

Model tests results, Computational Fluid Dynamic (CFD) calculations, sea trials measurements and long-term monitoring data.

Develop

Recommendations and best practices on ship scale CFD.

Improve

Confidence in CFD to make more accurate energy-efficiency predictions.

Ship scale validation cases

| MV Regal | JoRes1 Tanker | JoRes2 RoRo ferry | JoRes3 Cruise liner | JoRes4 Deniz tug | JoRes5 bulk carrier | Lucy Ashton | ||

|---|---|---|---|---|---|---|---|---|

| Geometry files formats | .igs .stp .stl | .igs .stp .stl | .3dm .igs .stp .stl .dbs | .igs .stp .stl | .igs .stp .stl | .igs .stp .stl | .igs .stp .x_t | |

| Dimensions | Length between perpendiculars, m | 138.0 | 178.5 | 170.0 | 226 | 18.28 | 182.0 | 58.1 |

| Breadth moulded, m | 23.0 | 32.26 | 27.7 | 32.2 | 7.46 | 32.26 | 6.4 | |

| Model tests | Model tests at the trials draughts | SINTEF and CSSRC | SSPA and HSVA | N | N | N | N | 6 models |

| Geometry details | Energy Saving Device (ESD) | N | PBCF, skeg, rudder plate | Twisted rudders | Twisted rudders | Ducts | Pre Swirl Stators | N |

| Propeller | 1FPP, 4 blades | 1FPP, 4 blade | 2CPP, 4 blades | 2FPP, 5 blades | 2FPP, 4 blades | 1FPP, 4 blades | No :) | |

| Average Weld seams width, mm | N | 24.5 | 22.2 | N | N | N | N | |

| Information about Anodic protection | Y | Y | Y | Y | Y | N | Y | |

| Information about Bulge keels | Y | Y | Y | Y | Y | N | Y | |

| Roughness | Equivalent sand grain hull roughness, µm | 440 | 53 | 17 | 15 | 66 | 53 | 59 - 97 |

| Equivalent sand grain rudder roughness, µm | 440 | 63 | 22 | 230 | 132 | 63 | N | |

| Equivalent sand grain propeller roughness, µm | 6 | 4 | 3 | Y | Y | 4 | n/a | |

| Trials condition | Deep water trials | Y | Y | Y | Y | Y | Y | Y |

| Shallow water trials | N | N | N | Y | N | N | N | |

| Speed and Power trials | Sea trials speeds, kn | 9.03 10.96 11.76 12.82 | 8.96 11.25 13.34 14.14 | 16.66 | ~12 | ~6 ~7.5 ~8.5 ~10 | 13.65 15.25 16.02 16.32 | 5-15 |

| Draughts | Ballast | Loaded | Ballast | Ballast | n/a | Ballast | n/a | |

| Propeller torque measurements | Y | Y | Y | Y | Y | Y | n/a | |

| Propeller thrust measurements | Y | N | Y | Y | N | N | n/a | |

| PIV flow measurements | N | Y | N | N | N | N | N | |

| Cavitation observations | Y | N | N | N | N | Y | n/a | |

| Pressure pulses measurements | Y | N | N | N | N | N | n/a | |

| Drone videos of wave pattern | Y | N | N | N | Y | N | N | |

| Bridge videos of wave pattern | Y | N | N | N | N | N | N | |

| Trials with and without ESD | N | N | N | N | N | Y | Y | |

| Manoeuvring trials | Zig-zag 10 deg tests | N | N | N | Y | Y | N | N |

| Zig-sag 20 deg tests | N | N | N | Y | Y | N | N | |

| Turning circle | N | N | N | N | Y | N | N | |

| Inertia Stop | N | N | N | N | Y | N | Y | |

| Acceleration | N | N | N | N | Y | N | Y | |

| Crash Stop | N | N | N | N | Y | N | N | |

| Bollard pull | N | N | N | N | Y | N | N | |

| Long term monitoring data | Y | N | Y | Y | N | N | N |